Our company provides the following production processes and services:

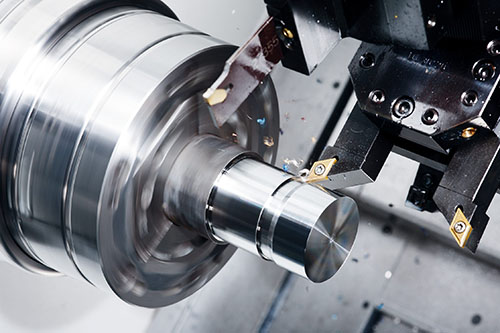

TURNING

We use CNC-controlled 2- and 3-axis lathes with driven tools for the production of highly precise and complex parts from a diameter of 5 mm to 520 mm with a maximum length of up to 1200 mm.

MILLING

On our 5-axis vertical machining centers, we produce a wide range of products from the smallest dimensions up to dimensions of 500mm x 700mm x 550mm. Milling components weighing up to 500 kg is not a problem for us.

GRINDING

The cylindrical grinder allows us to process workpieces with a high degree of dimensional accuracy and a defined surface quality with a maximum grinding diameter of up to 125 mm at a maximum length of 500 mm.

QUALITY CONTROL

Quality is the focus of our attention at the beginning, during and at the end of every production operation. When carrying out activities, our employees assume the same level of responsibility as the company's management, as we work with a certified quality management system in accordance with ISO 9001:2016. Our company is authorized to transfer the marking of metal materials with certificates according to EN 10204 – 2.1, 2.2 or 3.1 for the purpose of ensuring the traceability of the material. Issuing measurement protocols, protocols on the transfer of marking of materials and providing material certificates in case of customer's request is a matter of course for us.

ISO 9001:2016 certificate

Certificate for transferring the marking of metal materials

SURFACE TREATMENTS AND HEAT TREATMENT

In cooperation with reliable and high-quality cooperation partners, we provide our customers with various treatments such as annealing, quenching and tempering, vacuum hardening, induction hardening, nitrocarburizing, plasma and gas nitriding, blackening, galvanic zinc coating, zinc-nickel coating, phosphating, anodizing and many others.

PROCESSABLE MATERIALS

As part of our production program, we can machine chip various types of materials such as:

- structural, tempered, case-hardening, free cutting steel, steel for pressure vessels

- stainless steel

- bronze, copper, brass

- aluminium and its alloys

- cast iron

- supplied forgings and castings